Hi,

On Folk Fuzz hardware and mechanics:

It's possible to build this into an MXR sized box, but if you'd like to employ the switching options it is easier to use a twice as wide box.

Remember to plan for battery placement inside the box if you like to be able to use battery.

The larger box will make an easier build.

Securing potentiometers and jacks with locking washers helps keeping the unit sturdy.

A general tip is to plan placement of knobs and optional switches, jacks and LED before drilling the box.

You can use a batteryoperated drill, that is what I do unless I drill many boxes.

The main advantage of battery operated drilling is that if the drill bit gets stuck, the drill stops imediately-a wallpowered drill will continue to rotate for about a minute, something that can be dangerous and you will need to be prepared for this.

There are pure aluminium boxes and those are easily drilled, but there's still a risk at drillbit getting stuck.

I'd like to have all parts prepared before building and would mark all holes on the box and drill and paint and while that dries I'd make the pcb.

Once you have built the board it is helpful to build the mechanics into the box so unit can be fully tested.

If something doesn't work or you run into trouble post about it and we can see how it can be solved.

I have seen a site that had all kinds of knobs but I don't remember the location perhaps somebody does?

There are a number of mechanical parts needed and here goes

1x Stereo Telejack

1x Mono Telejack

1x1M linear or preferably reverselog pot

1x100K linear pot

1x50K logarithmic pot

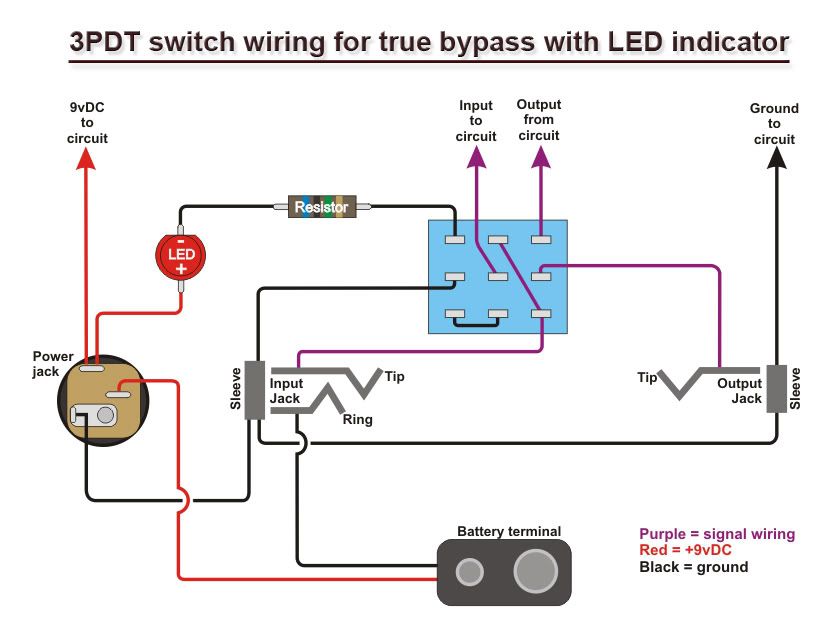

1x3PDT footswitch ( blue Taiwan is just fine)

1x optional metal washer for the footswitch- personally I think that looks better but those will have to be bought seperately.

1x LED clip

1xBatterysnap- hardtype lasts longer

1x Box, the size of which depending on how many options you'd like to include

2x lockingwashers for the telejacks

3x lockingwashers for the potentiometers-some potentiometers come with a guiding pin and those can use an extra hole in the box and will then not need any locking washer

3x knobs

To wire the outboard parts I'd recommend using stranded wire with a core of at least five pieces and so the wire can flex.How to wire the outboard parts is also likely a topic in itself and that can be discussed in this thread and you can choose the most comfortable way. I'd like to make sure that wires aren't stretched anywhere and that there is no tension as that greatly reduces the risk of a wire breaking.

You will also need some way of securing the pcb inside the box. I use neoprane, which is the same kind of rubber as used in diver's suits, but there are many ways and only one that you'd mostly prefer and this could be a topic in itself as I am sure there will be some clever options here and this might also be discussed in this thread.

I'd also recommend finding a way to secure the battery wires and making sure the battery sits snugly in the box without rattling.

Lastly there are many sources for mechanical parts and those I use may not be available for you as those available to you might not be to me, but let's see where parts can be had and what they will cost.

In building a guitarpedal the most expensive parts are just the mechanics.

Anyway have fun

BJ

Mechanics of the Folk Fuzz

Moderator: Moderators

6 posts

• Page 1 of 1

-

BJF - Posts: 522

- Joined: Tue Feb 27, 2007 4:43 am

- Location: Stockholm

- Guitars:: Les Pauls, V with P-90's and humbuckers, strats,tele duo-jet and expanding; pick ups mostly Lundgren or BJF/ Lundgren

Danelectro Barython - amps: MP CS-40, MP101, Hiwatt Custom 200, Hiwatt Custom 100, VOX AC15

Fender Blues De Ville, Fender Super Reverb, Marshall 5150 through various speakers - pedals: 42

Re: Mechanics of the Folk Fuzz

Thanks for all the help and tips on this fun project Bjorn!! I can't wait till my kits arrive.

- nibus

- Posts: 111

- Joined: Fri Feb 29, 2008 3:36 pm

- Location: In God's Country

- Guitars:: LP's, Partsocaster Strat, Washburn, Hamer

- amps: Traynor YCV40 / Fender DeVille 2x12

- pedals: 16

Re: Mechanics of the Folk Fuzz

UPDATE: All but 9 people on the current list have paid which is pretty great for a project like this. The boards will arrive at my door on September 5th and I would like to place the order for the parts no later than September 2 so that I get everything at the same time. Which means I would really like everyone who wants kits to either confirm that they are still in or send payment so I know how many components to get. A few days ago I sent everyone on the list a PM with payment instructions so please let me know if you still want a kit or not.

Pricing remains at $10/board and $20/kit until I ship out the first set of orders which should be about September 10th. There are only 100 boards total and 60 of them are spoken for.

Pricing remains at $10/board and $20/kit until I ship out the first set of orders which should be about September 10th. There are only 100 boards total and 60 of them are spoken for.

Part time pedal builder with a day job now with a web site http://www.fromelelectronics.com

- jfromel

- Posts: 201

- Joined: Sun Aug 10, 2008 3:02 pm

Re: Mechanics of the Folk Fuzz

Can anyone provide any tips on how the 3PDT is to be wired (which posts to the jacks/power, to the board)??

Thanks!

Thanks!

- soli'd

- Posts: 17

- Joined: Fri Oct 26, 2007 8:26 am

- Location: Georgia, USA

Re: Mechanics of the Folk Fuzz

Power Chords don't contain a third, so the maj&min qualities are not present. Heavy distortion adds harmonic content, and only perfect intervals have enough consonance to be clearly articulated at high distortion levels_DFunk

-

noelgrassy - Posts: 39

- Joined: Thu Aug 28, 2008 4:25 am

- Location: Vaccuum Tube Valley

Re: Mechanics of the Folk Fuzz

You da man. Muchas gracias

- soli'd

- Posts: 17

- Joined: Fri Oct 26, 2007 8:26 am

- Location: Georgia, USA

6 posts

• Page 1 of 1

Return to Folk Forum (DIY projects)

Who is online

Users browsing this forum: No registered users and 2 guests